PET bottle matrerials must be dried by a dehumidifying drying system. The working process of the dehumidifying drying system is as follows:

First, dry hot air enters the raw material from the bottom of the hopper, absorbs moisture contained in the raw material from bottom to top, and preheats the PET material.

Second, the humid air from the upper part of the hopper is cooled (below 65 degrees), filtered and then passed to the dehumidification bed.

Third, wet air is dehumidified in the dehumidification bed.

Fourth, the dry air from the wet bed is heated and returned to the hopper again.

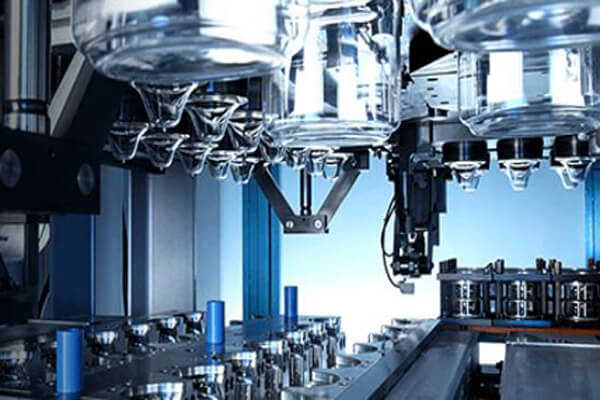

high level pet bottles

The dewetting bed is a molecular sieve composed of synthetic crystalline metal aluminosilicate which has been dehydrated during the manufacturing process. The main characteristic of the dehumidified bed is that it releases moisture when heated and absorbs moisture when cooled until the humidity is saturated. The dehumidified bed with saturated humidity can gradually release moisture during the subsequent heating process, which is called regeneration of the dehumidified bed. Therefore, in order to achieve continuous operation of the drying system, the system is equipped with two dehumidification beds to work alternately.

pet machine

The ideal PET bottle drying conditions are:

First, drying temperature: 165 degrees - 175 degrees Excessive drying temperature is likely to cause a decrease in IV, while too low drying temperature will result in insufficient drying;

Second, dry air dew point: -40 degrees - 50 degrees Dry dew point will directly affect the PET drying effect

Third, drying time: 4hr - 5hr

In addition, a sufficient drying time of 170 degrees will significantly reduce the IV value. Therefore, during shutdown maintenance, the drying temperature should be reduced to about 120 degrees.

What should we pay more attention on choosing plastic pharma bottle

View More >How Can Plastic Vitamin Tube Keep Dry Environment

View More >Effervescent Tube with Spiral Desiccant Closure

View More >Copyright © Shijiazhuang Xinfuda Medical Packaging Co., Ltd. All Rights

MAKE AN ENQUIRY